|

No

sorry, not this Ferengi with a lust for profit and Gold-Pressed

Latinum, nor any one of the six types of sub-atomic particles known

as Quark flavours; up, down, strange, charmed, bottom and top. In

fact, this Quark flavour, the 2M, is a lightweight aerobatic soarer

for VTPR* or close-in slope manoeuvres from Fred Marie in Ireland. No

sorry, not this Ferengi with a lust for profit and Gold-Pressed

Latinum, nor any one of the six types of sub-atomic particles known

as Quark flavours; up, down, strange, charmed, bottom and top. In

fact, this Quark flavour, the 2M, is a lightweight aerobatic soarer

for VTPR* or close-in slope manoeuvres from Fred Marie in Ireland.

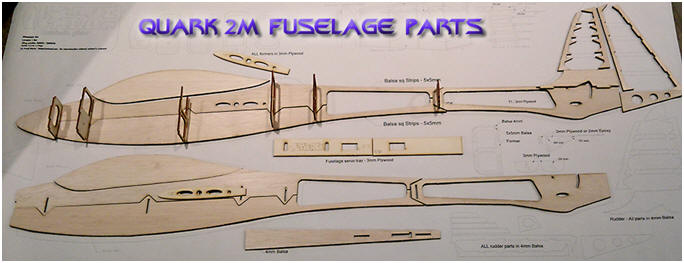

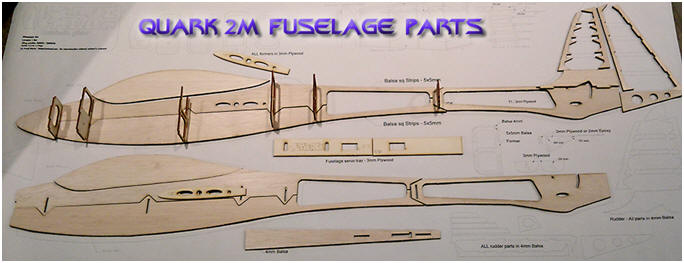

This QUARK balsa model

comes as a part-kit, a design by Fred Marie whom

I believe is a Frenchman; the model certainly looks like a French

VTPR type with a bulbous front end. The kit is all wood except for a GRP bellcrank. All the

parts for the fuselage, wings, rudder and elevator are laser cut

from balsa and lite-ply. However, you will need some sheet balsa and

wing tubes and dowels plus hinges, clevises etc. to complete the

model.

The two plans and instructions supplied refer to different

iterations of the model, I believe, which can be confusing as one recommends a

1m carbon tubular spar in each wing while the plans only show a

shorter carbon wing dowel tube with spruce or balsa spars. I balked

at the cost (£30+ inc.pp) of a 2 metres of carbon tube and carbon

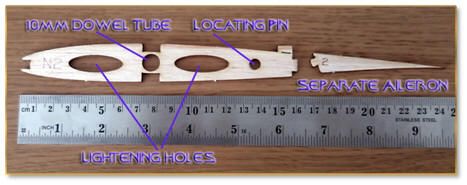

rod as wing dowels so I chose 10mm aluminium tube and a short piece

of 8mm diameter carbon rod for the main dowel with a smaller pieces

of 6mm carbon rod and ally tube for the locating dowel which I

already had.

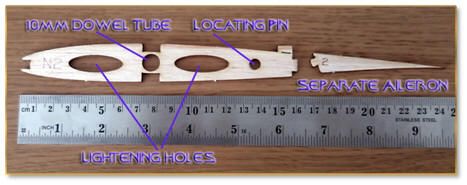

WINGS WINGS

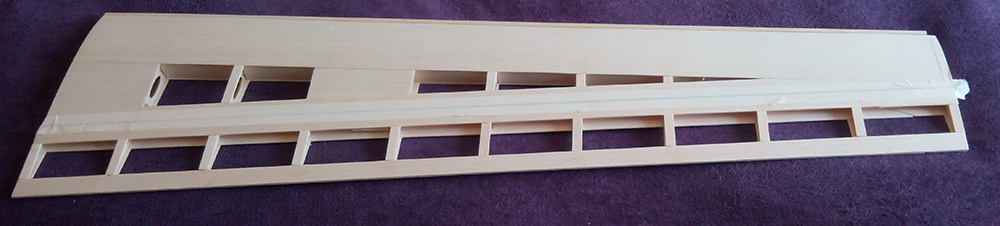

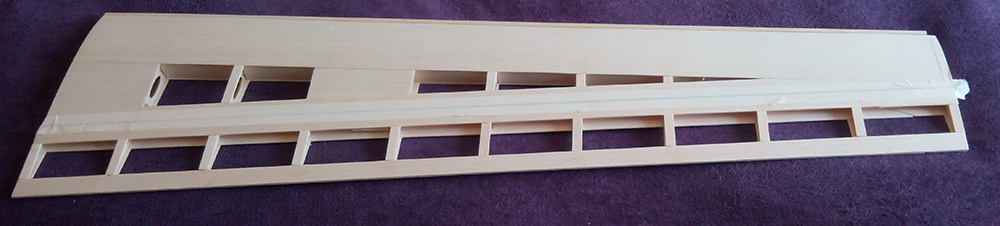

The wing construction is

straightforward, and because the wing ribs are laser cut, the parts

lock together tightly to make a light but seemingly strong wing. The

wing can be part or wholly sheeted. The ailerons and wings are

built-up separately and, like the fuselage and tail pieces, have

lightening holes to save every gram. The finished 2M model can come

out as light as 1.2kg but I had no way of knowing its final weight

until it was balanced. I intended to use a mix of Solartex

for the fuselage and transparent film for the surface covering, I

already had servos for the two ailerons, rudder and elevator (HS82MG

for the wings and HK* GoTeck) from other models. I considered

using a pair of Samsung 18650 or 4 Eneloop Pro cells

for the power supply, it depends on the balance and CG; I chose a

new cell (to me) as it happens.

Both the wing and tailplane are

built upside down and the ribs have lugs to support the inverted

surfaces as they are built, these are cut off later when the topside

of the wing is sheeted. Aiming to keep this model very light I chose

a balsa spar with vertical double shear webs each side of the spar

for the wings, the wing dowel is 8mm carbon tube in a 10mm aluminium

tube. One wing panel done

(and now up the right way) it just needs a little sanding then the

HS82 servo can be installed and the panel covered with film. There

are no flaps on this model only large 3” wide strip ailerons.

Designed with a built-in chamfer the leading edge of the aileron

really means that the wings have to be tape hinged on the top

surface. I chose to use Blenderm tape which, primarily

intended for skin wounds, is very sticky and quite flexible. This tape is

available from many pharmacies I should think, although I bought

mine from HK. The two panels came out at just 172g each

before final sanding, servos and covering which bodes well for a

lightweight model. Both the wing and tailplane are

built upside down and the ribs have lugs to support the inverted

surfaces as they are built, these are cut off later when the topside

of the wing is sheeted. Aiming to keep this model very light I chose

a balsa spar with vertical double shear webs each side of the spar

for the wings, the wing dowel is 8mm carbon tube in a 10mm aluminium

tube. One wing panel done

(and now up the right way) it just needs a little sanding then the

HS82 servo can be installed and the panel covered with film. There

are no flaps on this model only large 3” wide strip ailerons.

Designed with a built-in chamfer the leading edge of the aileron

really means that the wings have to be tape hinged on the top

surface. I chose to use Blenderm tape which, primarily

intended for skin wounds, is very sticky and quite flexible. This tape is

available from many pharmacies I should think, although I bought

mine from HK. The two panels came out at just 172g each

before final sanding, servos and covering which bodes well for a

lightweight model.

FUSELAGE

In

between cutting, gluing, pinning and waiting the second wing panel,

now going faster after the first one, I removed the parts for the

fuselage and laid them on the plan. The fin and rudder fit nicely

and, as you can see, the fuselage is a bit of a jigsaw puzzle of ply

and balsa presumably because the parts need to fit in a certain size

box for the Irish post. All straightforward and with the massive

plan on the floor, it looks easy to assemble and it is light. As I build, I am

thinking this 2M model could come out at under 1kg. I did make one

modification to the original model and that is in the nose. The nose

block is made by sandwiching together the eleven pieces of balsa and

ply supplied and then sanded.

|

|

|

Reasoning that the model would probably need nose weight I cut some of these pieces to create a

void in the nose block before gluing that would take a 100g+ chunk of lead as far forward as possible, if it were necessary. |

|

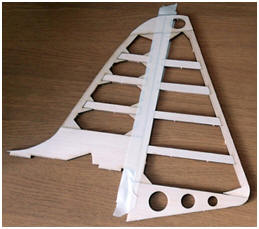

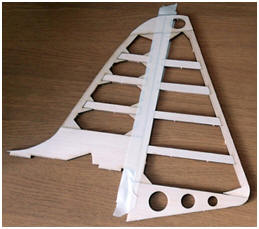

FIN & RUDDER

The fin and rudder are simplicity

itself and meant to be light; this is the framework but the fin

needs sheeting with 1/32” balsa (like the tailplane). The fin has a

carbon tube on the hinge line fixed into fuselage to make it a

bit stiffer and more rugged. I used 0.8mm obechi veneer as I had

insufficient 1/32” balsa. It will have pull-pull cables. The tailplane halves proved

trickier than I first thought since the pre-cut ribs for it are very

delicate... I broke a couple. I could not find the correct size

carbon rod and a tube to fit so I used different sizes to those on

the plan. I sheeted with 1/32” balsa on the top and 1/32” obechi on

the bottom.

Before covering, they came out at just 22g for each half

and light enough I thought. I used two flanged ball races on the

fuselage for the rotating pivot; a change from the plan. I used

incredibly shiny clear film (backing film very hard to remove) from

HK… I bought a 5 metre roll for less than £7!!! It seems to work

well enough, better than the old Solarfilm in some ways. I made a

regular balsa pushrod, btw. |

|

ELEVATOR

I did suffer a little ‘builder

fatigue’ as I call it, as I thought about a Mad Stab*, tried it and

failed, so progress was slow. I added a couple of cheap aluminium

cased servos from HK for the elevator and rudder and I used a pair

of old HiTec 82s from another model for the wings. I used four

Duracell Ultra NiMH rechargeable cells (new to me) as the power

supply. Rated at 2500mAh they are a change from the more expensive

Eneloop Pro I normal use (these Duracells cost about £8 for 4AA).

When I finally finished the Quark

2M I had gone overweight, I missed my 1kg target. The 172g nose

weight that I added didn’t help. The A.U.W. was 1.166kg. This

equates to a wing loading of 30.7 g/dm2, almost exactly

10oz/sq.ft. |

|

Not everything

went according to plan, my building skills have deteriorated over

the years! This model finishes my 2018 winter building. I started by

re-furbishing my 2.7m Jedi aerobatic from France… and pressing a new

pair of wings for it, then it was this Quark. All that remains

is to fly both of them. One heavy and one light, I have a feeling my

favourite models will still be my Kinetic and my Raptor though. |

-

Quark ‘Flavours’

-

Span: 2m

-

Length: 1,40 m

-

Surface AREA: 38 dm²

-

Wing Profile: SB96V/SB96VS

-

Weight 1,2 - 1,7 kg

-

VTPR =

Voltige Très Près du Relief

-

Mad Stab: +/- 90º

movement

-

HK: HobbyKing.com

-

Fred Marie:

www.islandmodels.ie

|

|

|

|

|

No

sorry, not this Ferengi with a lust for profit and Gold-Pressed

Latinum, nor any one of the six types of sub-atomic particles known

as Quark flavours; up, down, strange, charmed, bottom and top. In

fact, this Quark flavour, the 2M, is a lightweight aerobatic soarer

for VTPR* or close-in slope manoeuvres from Fred Marie in Ireland.

No

sorry, not this Ferengi with a lust for profit and Gold-Pressed

Latinum, nor any one of the six types of sub-atomic particles known

as Quark flavours; up, down, strange, charmed, bottom and top. In

fact, this Quark flavour, the 2M, is a lightweight aerobatic soarer

for VTPR* or close-in slope manoeuvres from Fred Marie in Ireland. WINGS

WINGS Both the wing and tailplane are

built upside down and the ribs have lugs to support the inverted

surfaces as they are built, these are cut off later when the topside

of the wing is sheeted. Aiming to keep this model very light I chose

a balsa spar with vertical double shear webs each side of the spar

for the wings, the wing dowel is 8mm carbon tube in a 10mm aluminium

tube. One wing panel done

(and now up the right way) it just needs a little sanding then the

HS82 servo can be installed and the panel covered with film. There

are no flaps on this model only large 3” wide strip ailerons.

Designed with a built-in chamfer the leading edge of the aileron

really means that the wings have to be tape hinged on the top

surface. I chose to use Blenderm tape which, primarily

intended for skin wounds, is very sticky and quite flexible. This tape is

available from many pharmacies I should think, although I bought

mine from HK. The two panels came out at just 172g each

before final sanding, servos and covering which bodes well for a

lightweight model.

Both the wing and tailplane are

built upside down and the ribs have lugs to support the inverted

surfaces as they are built, these are cut off later when the topside

of the wing is sheeted. Aiming to keep this model very light I chose

a balsa spar with vertical double shear webs each side of the spar

for the wings, the wing dowel is 8mm carbon tube in a 10mm aluminium

tube. One wing panel done

(and now up the right way) it just needs a little sanding then the

HS82 servo can be installed and the panel covered with film. There

are no flaps on this model only large 3” wide strip ailerons.

Designed with a built-in chamfer the leading edge of the aileron

really means that the wings have to be tape hinged on the top

surface. I chose to use Blenderm tape which, primarily

intended for skin wounds, is very sticky and quite flexible. This tape is

available from many pharmacies I should think, although I bought

mine from HK. The two panels came out at just 172g each

before final sanding, servos and covering which bodes well for a

lightweight model.