|

THE MINIVECTOR

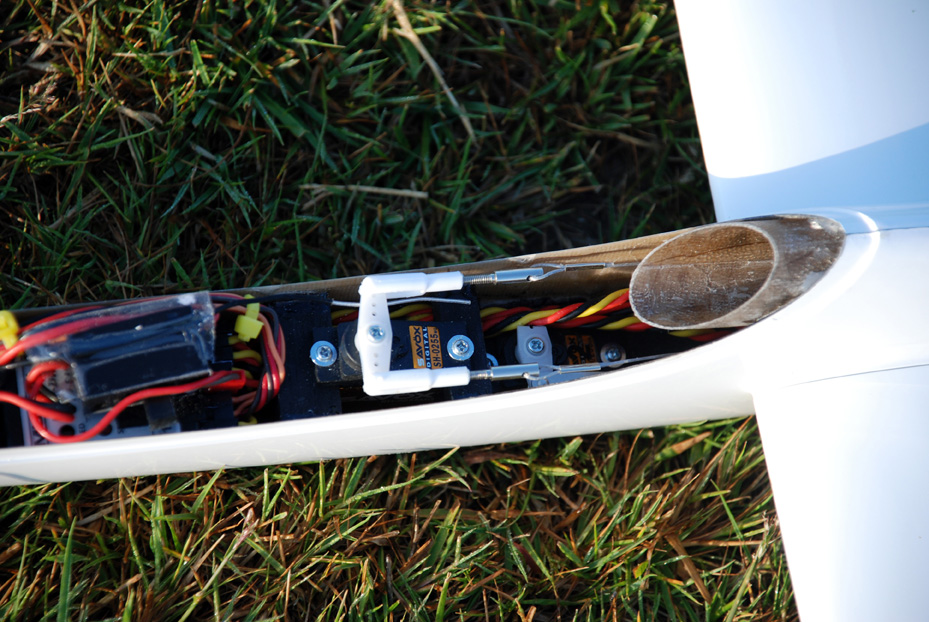

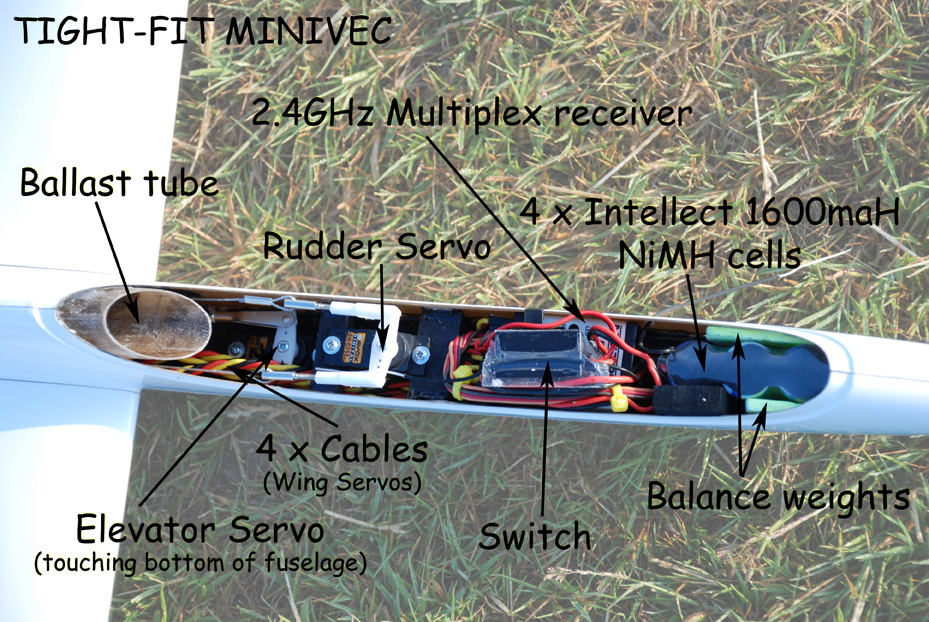

My Minivec was a pain to put together. I used the recommended Savox,

metal gear, digital wing servos but had to cut the lugs off them to

fit them in the correct place for the aileron and flap horns, the servos don't go where you think they ought so the

holes in the shrouds consequently didn't fit, I had to make some

others.

I also ripped out the stiff-ish elevator and rudder snakes and

replaced them with a carbon elevator pushrod and a closed loop rudder. The

elevator servo must touch the bottom of the fuselage if you do this

modification although it is difficult to do (getting the elevator

horn clevis in place requires cutting into the fuselage/rudder post. Oh yes,

having cut it off, I made the rudder larger too (but mine shown were still needs to be even bigger).

It was difficult to fit all this stuff in the narrow fuselage (a model feature pioneered by brother David in his 80s

Aeolus). The enormous ballast tube in the fuselage is overkill but apparently one

must use it as it seems to be part of the fuselage design.

I'm still worried about 4 instead of 5 Intellect NiMH cells running six digital

servos though, if I can get them to fit I might try Eneloops. Looks nice, the surface finish is

excellent, everything fits (except the

wing servos on my version); the mega, square carbon dowel only needed

the lightest of sanding. The tail fits well. The canopy is cut to a

nearly perfect fit and is not carbon. As I said earlier the snakes

were stiff. It needed a piece of moulded lead

in the nose plus some extra (see image left). The use of the

'Multiplex' green plugs and sockets means the model goes together

really quickly on the slope, holding the wings on with tape however

is a problem—there's not much room on the wing fairings for sticky

tape. Wings—trouble is, I'm not sure what the wings are like

inside; David tells me they're not too hot after seeing the insides

of his after replacing two busted

wing panels which sprang apart in a crash and later mid-air.

It flies beautifully but... not for the beginner though, use full ballast and I reckon you'll wreck it no time. Lovely plane now I've fiddled with it. Update August 2011—Had a little prang—landed flat on the slope with a bang—fuselage split open and cracked —damaged the wing root too—luckily it went back together, more or less, with a little cyano. See another Minivec video at www.vimeo.com/21365904 Get it from www.sloperacer.co.uk |

Click this image for a short headcam video using Keyring Camera #11

|