|

SVOLAZZO pour Voltige Totale |

|

|

J'aime les modèles français; au fil des années, j'en ai eu quelques-uns, de l'Axel wing-twist original au Jedï, au Quark, et plus récemment au MadSlide que j'ai décrit sur mes pages ici. My latest build is the Svolazzo, a ‘short kit’ containing most of the laser parts needed but no full accessory pack. The kit seems to be by special order as it’s not always in stock. This model comes from the François Cahour and Stéphane Combet stable in France. There is plenty of information on Stéphane's web pages, as well as Phillipe Jambon, another prolific French builder. There are YouTube instructional videos as well by both fliers, even including the programming of OpenTx (in French of course). This model is designed for 'Voltige Totale' (sic), sometimes called Ultrabatics, and this includes peculiar manoeuvres on the very edge of the slope by the use of +/-90º elevator and +/-90º rudder movements along with wing-twist plus regular ailerons and flaps. Flips and true flat-spins are possible. It is supposed to be a light 2.2m model coming in at 1.4-1.5kg and I came in under at 1435g before final CG adjustment. |

|

|

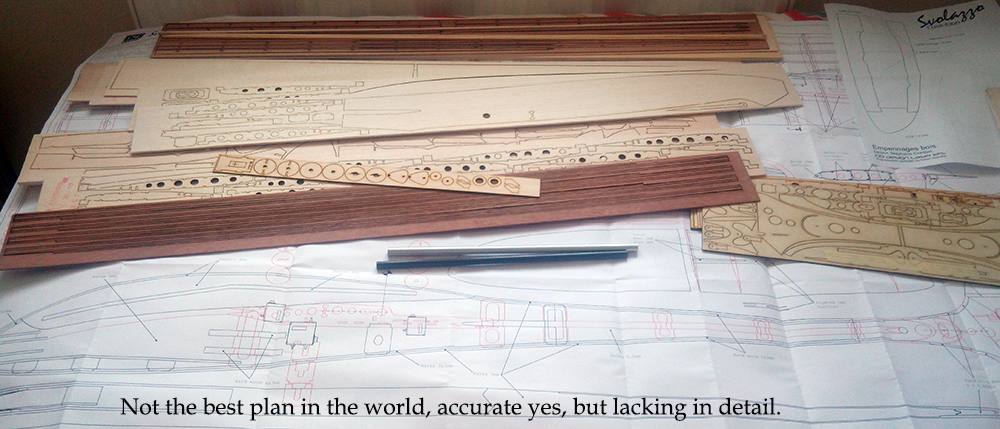

The kit comes with nearly all the parts pre-cut by laser and

actually uses 4 types of wood…balsa, obechi, plywood and walnut, a

type of wood I never used before. Be warned now because this model

will be a challenge to build, I found it so in any case. There are

no instructions per se just the plan and the web pages. Be

warned too that your hands will be black with soot from the laser

cut edges of all the parts, especially the walnut. EMPENNAGES (Tail feathers) I started with the tailplane and rudder; these are straightforward except perhaps the choice of a pair of 2mm rods for the tailplane. I may have chosen a 3-4mm carbon and a 2mm actuator. The rudder, which has to move through 90º each way, has a small elliptical pulley just above the top hinge of the rudder. I got it right eventually but an odd thing to see. Circular pulleys will drive the elevator and rudder elliptical pulleys on their respective servos using a very thin Dyneema thread, which I doubled to make sure it did not break with the subsequent problems that would cause inside the fuselage. |

|

|

|

|

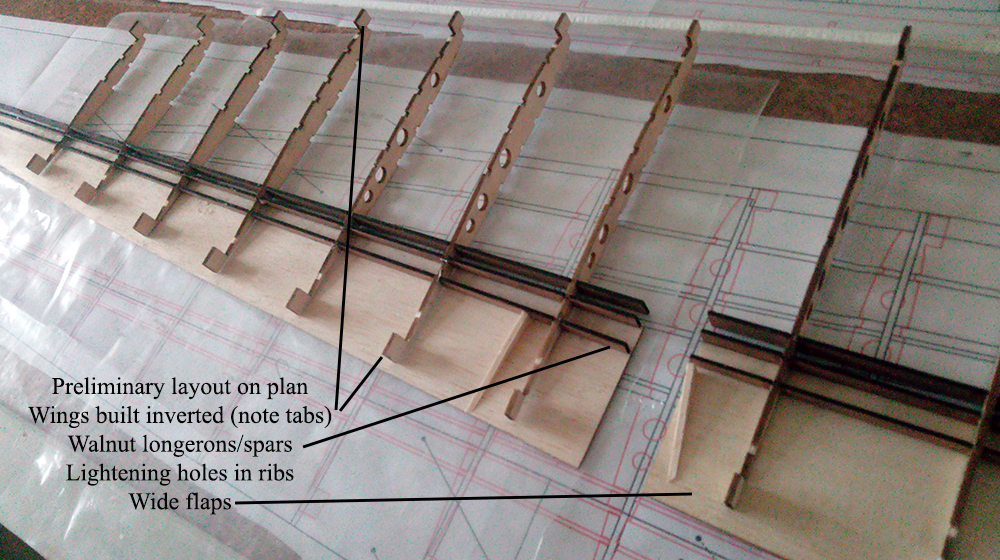

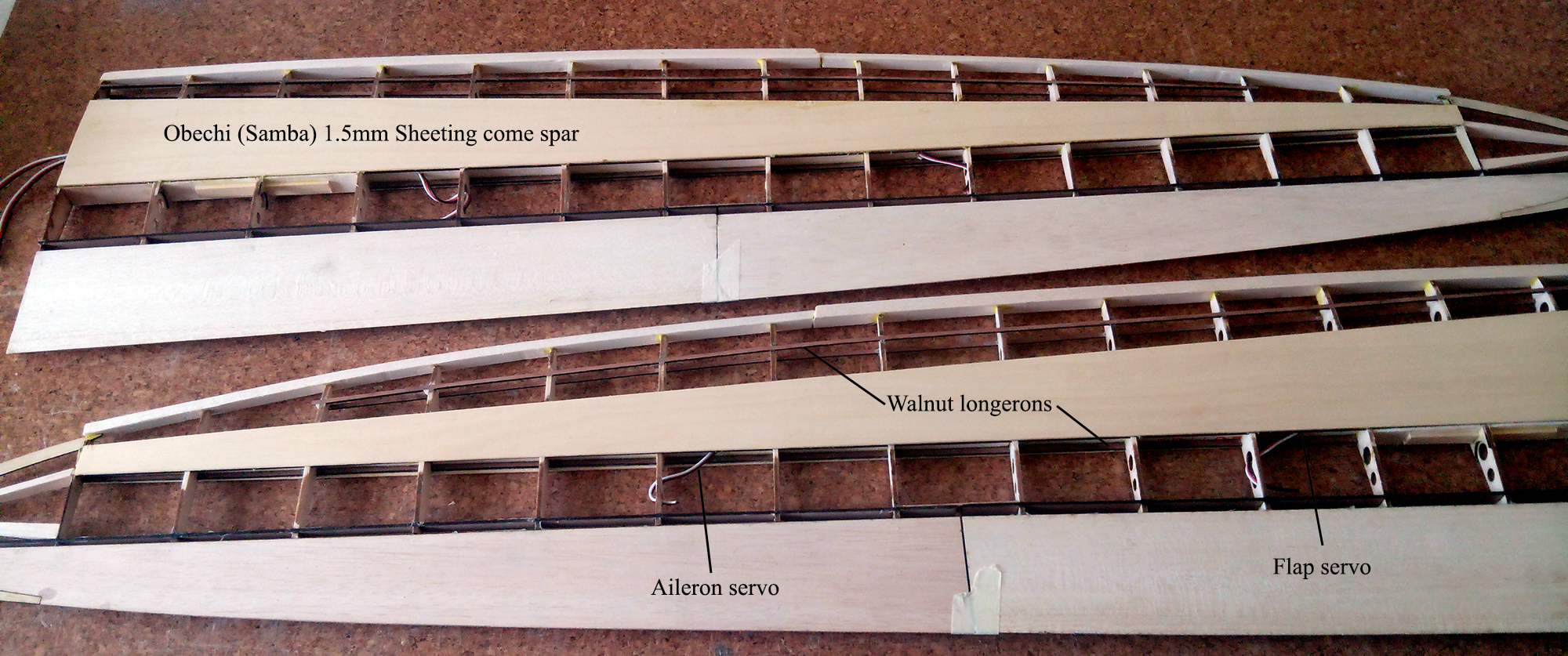

WINGS I made the wings next, again not easy, but I got there in the end. Weirdly, the model has no sheeting on the underside of the flaps and ailerons. I did in fact modify the ribs so that I could cover the surfaces with 1/32" balsa where there was no sheeting for my own satisfaction. You need to think carefully about modifying the wing mind you. As this model has both wing twist AND ailerons the supplied10mm carbon joiner is a loose fit in the aluminium dowel tubes since it must allow the wings to rotate... there are no ball race bearings. Necessary slop I guess but other modellers would find this odd. Ball races may have been a better choice but I didn't design this lightweight model and it's only meant for slow VTPR (close-in) aerobatic flight. |

|

|

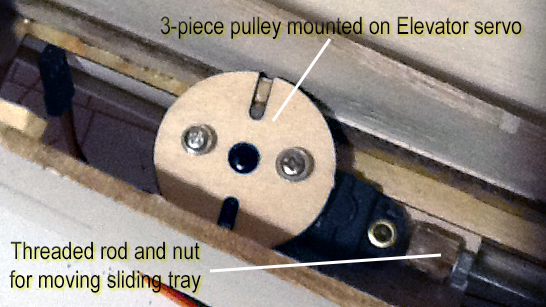

FUSELAGE The core of the fuselage is this internal ply structure designed to take the three servos, rudder, elevator and wing twist. I made it first before adding to the balsa outer. The wing twist servo is mounted vertically, btw, which activates the 'pitcheron wings' by means of a pair of 2mm pins from the wing roots through ball links on the servo. The rudder servo is easy enough although it needs a pair of turnbuckles to keep the Dyneema control cables tight should they slacken. Once set up, with loose hinges, it really does move through 90º. The elevator servo is mounted in a sliding tray (see image here), which is moved back and forth by means of a rotating nut on a threaded rod. This is what tightens the pull-pull elevator cables and keeps them taut in place of turnbuckles. They can be tightened/loosened by turning a nut on the threaded rod. When this has all been worked out (without any help from the plan but looking at the website), the rest of the balsa fuselage is constructed around this assembly.

I shall not bore you any longer but I can say

that this was a very difficult build for me. I covered it in

polyester film from HobbyKing (very cheap but good) and

Orastick. I then had the problem of programming the seven

servos. That was a challenge for me too… ailerons, flaps, snap flap,

reflex camber, thermal camber, compensations, normal rudder and

elevator then 90º Mad elevator and Mad 90º rudder, a couple of

curves and logical switches and then the wing twist as well. I

reckon Mike Shellim would have had a field day with this and even

run out of mixers on OpenTX.

I like the fact that it came out at just over 1450g for a 2.2m model. I like it because you have to make yourself and not a cheque-book model. I like it because it is unusual. I disliked the use of Depron for the canopy, I disliked small things like the pulley discs rub against the fuselage sides, I disliked the awkward wing twist mechanism and wondered if it is necessary except for very special manoeuvres. I disliked the half-sheeted Jedelsky style ailerons and flaps. And then I found a weak point in the construction, a break at the first bulkhead. Busted fuselage but wings, tailplane, rudder, servos all OK. A 'flat' crash landing at the bottom of the slope. Cause of crash is believed to be spring piano wire holding wings together coming off after aerobatics. Hey ho! On to next model with salvaged servos, I shall not be repairing this one. RESOURCES

|

|

|

Buy the kit here: http://www.cddesign01.com/ Read these pages: https://voltige-planeur-rc.net/2020/01/24/svolazzo/ And especially this: http://ph.jambon.free.fr/mes_modeles/Svolazzo/SVOLAZZO.htm |

Svolazzo Videos Stéphane Combet: https://www.youtube.com/channel/UCocDAjUfuTzs6sudO2wxQgQ Phillipe Jambon: https://www.youtube.com/channel/UCthiELnkDNdeWKgcp7It6Ow/featured |

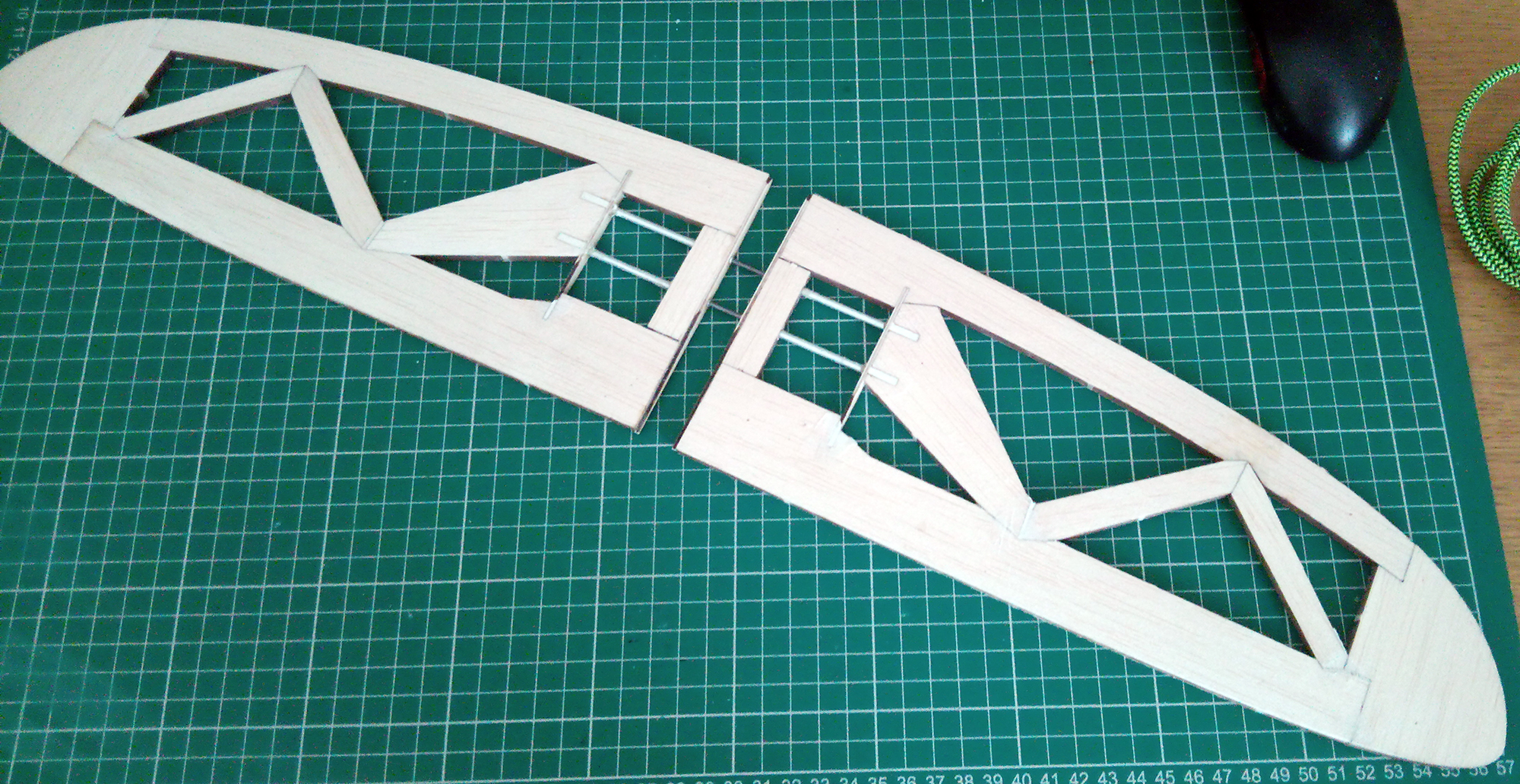

The

back end can be problematic because there is another elliptical

pulley to make and set in the correct position; i.e. at right angles

to the wings, rudder and stab and free to move. This is the time to

add the control cables, before the fuzz is covered. The canopy is

over-sized

The

back end can be problematic because there is another elliptical

pulley to make and set in the correct position; i.e. at right angles

to the wings, rudder and stab and free to move. This is the time to

add the control cables, before the fuzz is covered. The canopy is

over-sized